Diesel Cure Blog

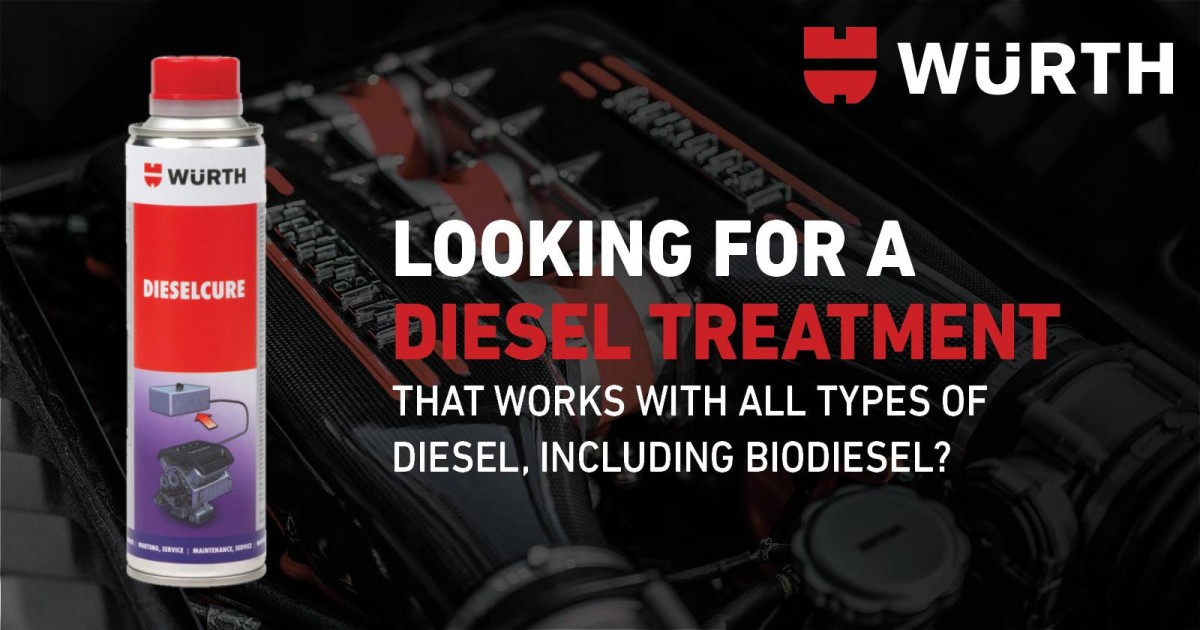

In the world of generator businesses, silent generators have emerged as a popular choice due to their noise-reducing capabilities. designed to provide a quiet and uninterrupted power supply, there is nothing more frustrating as investing in a generator only for it to fail to start when you need it the most.

While regular care and maintenance can significantly improve performance, it's often the simplest issues that can cause problems, such as the quality of fuel – even on the most advanced silent generators.

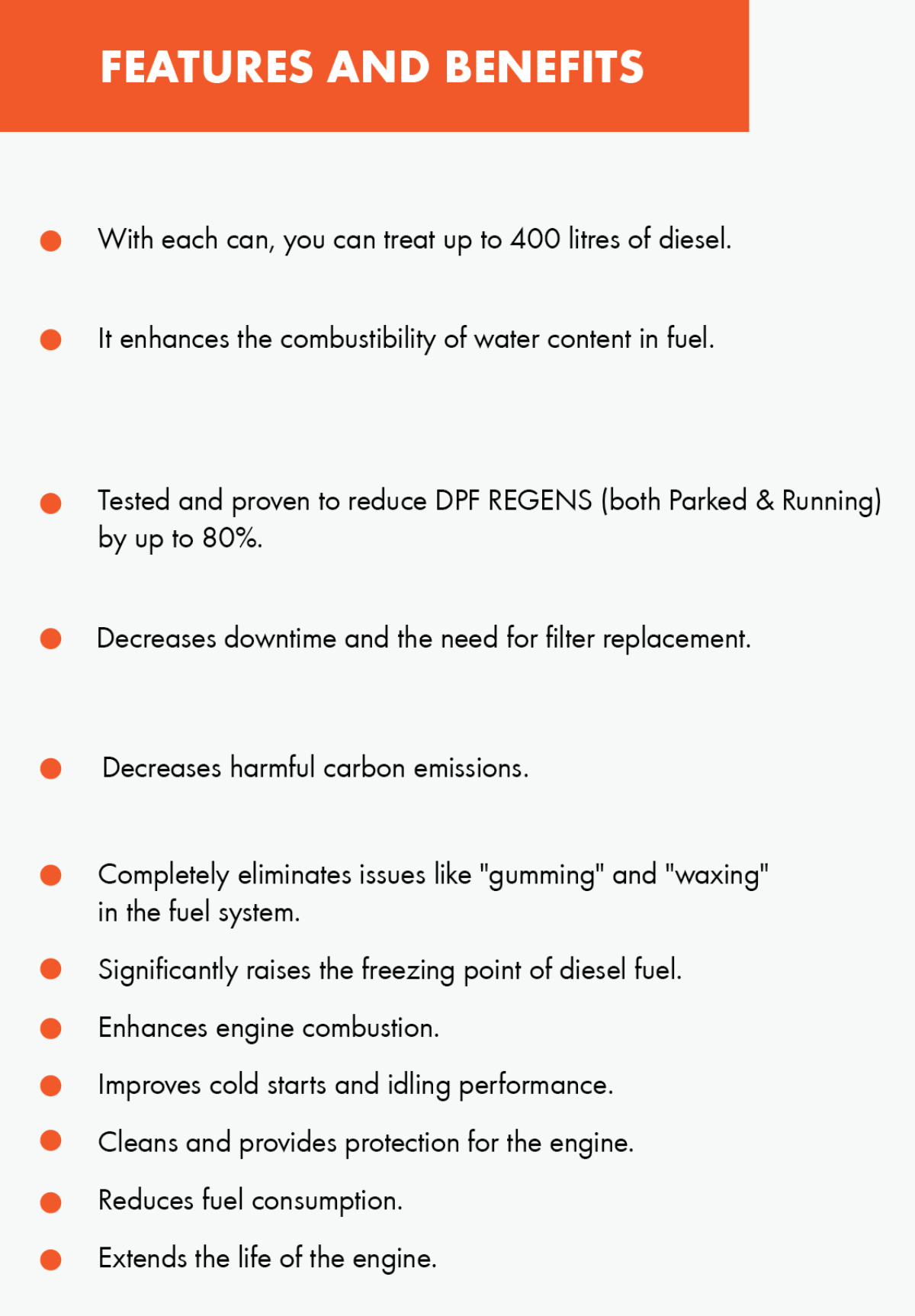

When it comes to aftermarket additives for diesel fuel, it is crucial that they do not compromise the stability, performance, or integrity of the diesel fuel system components.

Wurth Diesel Cure stands out as a unique product among all other aftermarket diesel fuel additives as it complies with diesel fuel specifications set by original engine manufacturers worldwide (View Compliance Letter )

This global compliance ensures the absolute safety of utilising Diesel Cure in any diesel fuel quality management system. This adherence to worldwide standards ensures that it does not pose any risk to the proper functioning of diesel fuel system components.

Common Causes of Diesel Fuel Quality Deterioration and Contamination

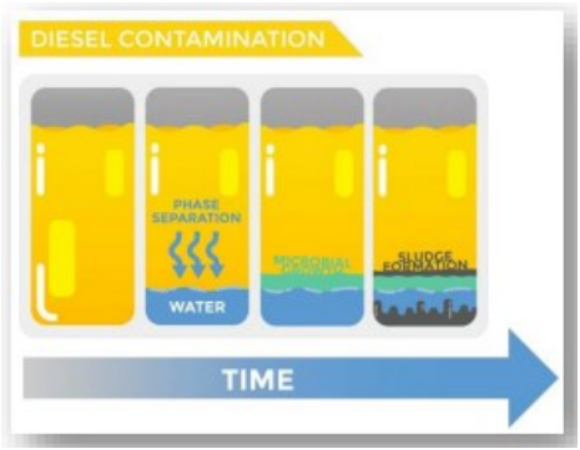

Diesel fuel contamination occurs during transportation, storing, manufacturing, and field-related maintenance, repairs and overhaul activities. Overtime, diesel fuel decomposes with age, leading to changes in its physical properties. This aging process is marked by a change in colour, causing the diesel fuel to adopt a brown hue (formation of a delicate brown resin) on any surface it comes into contact with.

Diesel Fuel is characterized also as a hygroscopic liquid indicating that it can absorb moisture from the atmosphere it is in

contact with. Water poses the greatest threat to both diesel fuel and the components of the diesel fuel systems. It serves as

the primary catalyst for the decomposition of diesel fuel, leading to a host of issues. The presence of water in diesel systems contributes to problems in diesel fuel such as but not limited to combustion, gelling up of diesel fuel, corrosion of diesel fuel system components, reduced lubrication of diesel fuel, and the creation of an ideal environment for bacterial growth.

Water is present in diesel fuel in two distinct forms: “Free water” and “Suspended Water.” Free water refers to moisture that has separated from the diesel fuel through condensation and settles at the bottom of diesel storage containers where the fuel is stored. On the other hand, suspended water consists of microscopic droplets formed either from individual molecules or as a result of fuel agitation in the diesel fuel. The droplets of this water are small enough to bypass diesel fuel filters and reach the crucial components of the diesel fuel system, and due to its buoyant nature, suspended water will remain suspended within the diesel fuel, regardless of its cause.

The corrosive and abrasive nature of suspended water molecules can lead to irreversible damage in essential diesel fuel system components, including pumps and injector nozzles. Over time, these molecules' abrasive particles wear down the injector nozzles, resulting in a change in the spray pattern. Such alterations negatively impact the efficiency of each nozzle, compromising the overall performance of the system

Acid (Water as a cause)

In the combustion chamber of diesel engines (the space between the top of the piston and the top of the cylinder), the production of Sulphur Oxide (SOx) and Nitrogen Oxide (NOx) occurs. Diesel fuel contains sulphur, which serves as a beneficial lubricant and anti-oxidant for both Diesel fuel and Diesel fuel system components. Additionally, nitrogen constitutes approximately 78% of the intake air in a diesel engine.

On their own, Sulphur Oxide (SOx) and Nitrogen Oxide (NOx) do not pose any harm to the diesel engine components or engine oil. However, the introduction of water into the process leads to the formation of Sulphuric acid (H2SO4) and Nitric acid (HNO3). While most of these acids are expelled through the exhaust valves into the exhaust system, a portion manages to bypass the piston rings and mix with the engine oil.

Consequently, the engine oil begins to decompose, resulting in a reduction in its lubricating properties and the formation of sludge. Moreover, these acids cause irreversible damage and wear to various engine components, including but not limited to bearings, piston rings, cylinders, and cam lobes. Additionally, these acids contribute to the hardening and failure of oil seals.

Sulphuric Acid poses its own set of issues when present in diesel fuel, resulting in the formation of a thin brown resin film – a condition commonly referred to as “gumming” – which directly affects the Diesel Fuel within the fuel pump and fuel injectors. As a consequence, the atomisation of the diesel fuel becomes inefficient. This inefficiency often leads to an oversupply of diesel fuel, noticeable by the excessive black smoke emitted from an engine.

Another well-known problem associated with diesel engines is the occurrence of sludge in the crankcase of the engine oil. This sludge is formed due to the combination of resin decomposition caused by acid and the presence of soot resulting from incomplete combustion of diesel fuel.

The presence of sludge significantly affects the viscosity of the engine oil, hindering its smooth flow and causing blockages in various oil components such as oil filters, hydraulic lifters, and tensioners. In severe cases, it can even lead to blockages in oil passages and galleries. Ultimately, the acidic nature of the engine oil accelerates engine wear and increases the risk of potential engine failure.

Biologicals (Water as a cause)

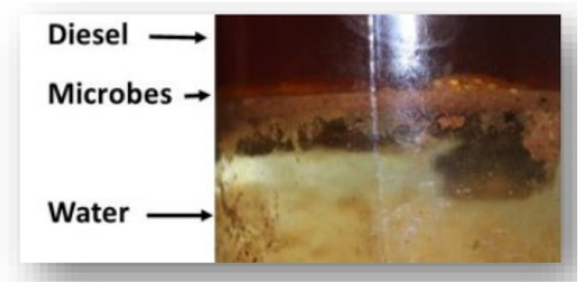

Diesel fuel inherently contains a certain amount of water which can further accumulate through the formation of water droplets as a result of condensation and water vapor, creating an environment conducive for the growth of microbes. The growth of microbes within diesel fuel heavily relies on the availability of water, which serves as their primary source of nutrition from organic and inorganic molecules.

It's important to note that certain microbial species can specifically target and consume various components of the diesel fuel, including hydrocarbons and other elements. When water contaminates diesel fuel, it creates conditions that promote the biodegradation of diesel fuel components, leading to changes in colour, heat of combustion, pour point, cloud point, as well as the detergent and anti-corrosive properties. These changes in Diesel fuel elements make them susceptible to active attacks by microbes.

Notably, molecules containing Sulphur are metabolised and consumed by various species of microbes, resulting in the production of high concentrations of hydrogen sulphide. Bacteria and fungi growth in diesel fuel can result in the production of various organic acids. These acids, along with their increasing numbers and concentrations, have detrimental effects on both the fuel itself and the components of the diesel fuel system. As fungi and bacteria reproduce, they form biomass, which accumulates on diesel fuel containers and filters. This biomass and slime production indirectly affect the diesel fuel by causing the accumulation of metabolic waste and dead cells, which form sludge at the bottom of fuel tanks. Beneath the sludge deposits, corrosion influenced by microbes occurs, along with sulphide and organic acid production.

The microbial composition of a sludge is determined by the specific physical and chemical properties of the sludge itself. As sludge accumulates in the diesel fuel, it can be drawn into the fuel system, leading to the formation of a biofilm on the internal surfaces of diesel fuel filters and fuel lines. This biofilm build-up often results in blockages, causing issues such as fuel starvation and leading to unscheduled repairs, maintenance, and downtime.

Brief product innovation and insight on pre-market trials

During the development and pre-market trials of Diesel Cure, a noticeable enhancement in the combustion performance of diesel fuel treated with Diesel Cure, as compared to untreated diesel fuel, was observed. This improvement can be attributed to Diesel Cure unique ability to treat water and effectively dissolve internal diesel injector deposits (IDID).

The following results were obtained during the trials:

Carbon Monoxide (CO) decreased by 12.5%

Carbon Dioxide (CO2) increased by 9.1%

Hydrocarbons decreased by 16.5%

Oxygen (O2) decreased by 2.2%

Nitrogen Oxide (NOx) decreased by 12.8%

Overall smoke opacity reduced by 7.8%

All the recorded readings clearly demonstrate an undeniable trend towards the improvement of combustion performance.

Fuel Conformity analysis

Diesel Cure has undergone comprehensive analysis and fuel conformity testing conducted by WEAR CHECK, and the resulting Analysis report is as follows: