All In One

What belongs together, stays together

The All-In-One DOS product is used as a medium strength thread locker, flange sealer, pipe sealant, and retaining compound.

The All-In-One is the perfect one stop product for a number of applications, such as:

- A medium strength THREAD LOCKER – perfect for ensuring that the fasteners remain in place, yet still being able to remove with hand tools.

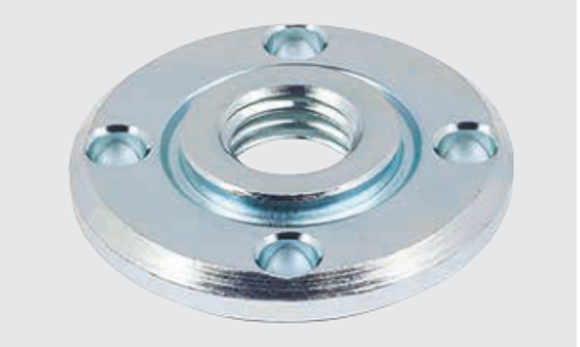

- FLANGE SEALER – which has gap filling properties of up to 0.5mm

- PIPE SEALANT – ensures that pipe joints do not fail under high pressure or extreme temperatures.

- RETAINING COMPOUND – it is the perfect product for mounting cylindrical parts – bearings, etc, and will also fill gaps up to 0.5mm.

ALL IN ONE AS FLANGE SEALANT ADVANTAGES

- Replaces conventional gaskets – reduces inventory.

- Fills all voids and gaps.

- No settling effects – No need for re-torquing.

- High resistance to solvents.

- Resists high pressure when fully cured.

- Protects against corrosion.

- Easy to remove sealant – ease of maintenance.

ALL IN ONE AS RETAINING COMPOUNDS ADVANTAGES

- Reduces or eliminates expensive machining operations, due to possibility of larger tolerances.

- Eliminates certain surface finishing requirements.

- Prolongs equipment life through better fatigue and corrosion resistance.

- Completely fills gaps and ensures absolute material contact.

- Even distribution of force.